The following is a collection of photo's I took while rebuilding the Multi disc clutch in my late 1928 Tudor. There was a recent discussion regarding the differences in the terms restore, and rebuild. In my opinion to restore something you bring the item back to it's original condition in form and function in all respects. Rebuilding is to bring the functionality back, but not original condition. In the case of this clutch, I was unable to restore it due to a lack of funds. I rebuilt it, to functionality, but it does not meet the original specs.

Because of the number of parts making up the clutch and the early problems found in use, the multi disc clutch was replaced by the single plate in late 1928. The teeth of the driven discs have to slide in the flywheel grooves for the clutch to function properly. As the facings wear, the dust produced had a tendency to clog these grooves. This happened starting with the front disc working it's way back until the clutch finally stop disengaging altogether. While this was a problem in 1928 it is a benefit to those of us rebuilding the clutches now. This early failure of some discs caused less wear on those linings. Less wear means that we can combine the best discs of several clutches to make one functioning clutch. Bear in mind that the rear driven disc and disc lining assembly are different than the remaining parts.

PARTS LIST

| A-7525 | Clutch assembly |

| A-7530 | Clutch driven disc and stud assembly |

| A-21700 | Clutch driven disc stud nut 5/16 -24 nsf (3/16 x 1/2) hex check nut |

| A-7539 | Clutch drum assembly |

| A-7545 | Clutch disc and lining assembly |

| A-7546 | Clutch disc and lining assembly -rear |

| A-7551-A | Clutch driven disc |

| A-7552 | Clutch driven disc -rear |

| A-7556 | Clutch spring |

| A-7561-A | Clutch thrust bearing hub |

| A-7580-A | Clutch thrust bearing assembly |

| A-7045 | Clutch thrust bearing snap ring |

| A-24405 | Clutch thrust bearing lubricator fitting (1/8 pipe thread lubricator fitting assembly (check valve type) |

| A tool that is almost impossible to do with out is the K.R. Wilson Multi disc clutch fixture. While it may be possible to rebuild the clutch with out this fixture, I would not like to attempt it. It is fairly straight forward in it's design and a similar fixture could be made. |

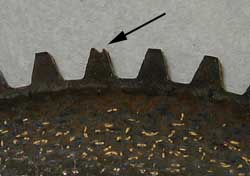

The first step is of course finding enough clutches to assembly into one functional clutch. Because of the design, the wear on the facing is greater on the front linings than on the rear. You also want to be sure the 'teeth' are not worn. Here's what your don't want to find:

LININGS WORN TO THE RIVITS |

'POINTY' TEETH |

Once you have what you feel is enough clutches, it's a matter of disassembly, cleaning painting and reassembly.

Mount the clutch in the fixture. Snug the handle on the thrust bearing, and loosen the five hex nuts. Tighten the handle, and remove the nuts.

Loosen the handle and remove the thrust bearing hub, and spring.

Now invert the fixture and the drum, allowing the driven and undriven discs to be removed. You can't just lift off the disc with the clutch in this position because of the snap ring on the drum.

Once you have everything apart, clean it all up paint what needs to be painted, and select the best of the linings you have available. If you can afford it Fort Wayne Clutch will re-line the discs. To reassemble the clutch look for the notch on the rear disc. This disc should be a 0.002 fit to the flywheel to prevent clicking and noise.

Start with the drum (snap ring down)place the A-7552 odd smooth disc then place the notched lined disc (A-7546) on the drum. Then alternate a smooth disc (A-7551-A) and lined disc (A-7545)until you have the stack made. Then install the driven disc and stud assembly.

|

|

This should give you a clutch that will provide many years of service. As the Ford service bulletins state, this is the type of clutch used in the lincolns and should be trouble free.

OH YEAH...DON'T RIDE WITH YOUR FOOT ON THE CLUTCH PEDAL

Page designed by Jim Mason July, 2007